Table Of Content

Even when using PP and PE you are limited on the types of additives and fillers you can use. If you need to use an engineering grade plastic such as polycarbonate or ABS then a traditional hinge would be a better fit. Inside, designers use smaller versions of them on cabinets to achieve a rustic feel. The long hinge leaves (or straps) add extra support for heavy gates or barn doors. Another type of pivot hinge allows doors to pivot open and closed both ways, much like the kitchen doors you see in restaurants. These spring-loaded hinges are larger and heavier than those made for cabinetry.

· Reduces Cost and Time

It’s worth noting though that these adjustments are only minor, usually just a couple of millimetres in any direction. The larger the doorway, the meatier the hinge has to be to keep the door operating correctly. I really like this technique too – You would be surprised by how many people haven’t seen or heard about it before. When customers drop by our US Office and see the examples we have on display, they always comment on the hinges.

Living Hinge Design: The Ultimate Guide

It involves casting a rubber mold with low-durometer urethane resins, which creates prototypes that perform poorly against wear and tear. The urethane casting method is not common in product manufacturing as its products made via the process are less durable and more likely to break or bend. Conventional metal hinges require assembly and fastening with a screw. However, the living hinge allows the hinge to come from the same material as the product. Therefore, it is possible to directly incorporate it into the product components. The living hinge comes from larger plastic sections and forms a bridge between both components.

Types of Hinges You Should Know

For quick-turn prototypes (3D printed parts in 24 hours), you can simply upload your files below for instant quotes in 3D printing and urethane casting. Hinges longer than 6 inches should be designed in two or more parts to improve hinge life. This both serves to make sure the hinge will bend in the center and that the part can deform enough for the hinge to have room to close. If the tight fit is on the inside member of the assembly, the pin’s two ends become sized and unsized as it is installed (handle section). The end of the pin that does not pass through the hole is larger than the end that has been sized by the hole. Therefore, measure the diameter of the unsized end to determine the minimum diameter of the free hole in the outside members.

– No Long Hinges

For example, in electronic enclosures, the amount of space is limited due to the sheer number of components located inside. If the space inside of the enclosure is not an issue, concealed hinges are a great option for engineers wanting to hide the hardware. A strap hinge is distinguished its long, narrow leaves — sometimes one, often both. That provides extra stability in heavy-duty applications, so they’re frequently used outdoors on gates. They’re also popular indoors for cabinets when you want the hinge to be a design element. Adding fillers is a common way to achieve certain requirements for the resin.

A scissor hinge can either lift up or drop down, and is used to control the opening of cabinet fronts as well as lids on things like cedar chests, hampers, tool chests, and radiator covers. The hinge opens and holds at a predetermined angle, requiring the application of pressure to close again. Ask RevPart for your gate location and we can give you a CAD drawing of your mold.

Strain is the ability of a material to accommodate deformation before failure. This is commonly measured by the part’s deformation in comparison to a reference length. These are two properties where ABS and PLA fail to make the grade (see Figures 1 and 2).

Samsung's Galaxy Z Fold 6 Is Coming in July, Report Says - CNET

Samsung's Galaxy Z Fold 6 Is Coming in July, Report Says.

Posted: Thu, 29 Feb 2024 08:00:00 GMT [source]

Your imagination is the only limit when designing and utilizing the kerf bend solution. Just follow the basic design guidelines in Figure 15 and you will be on your way to creating movable and aesthetically pleasing designs and parts. The two most common properties to measure quality in plastics are tensile strength and strain. Tensile strength is defined as the amount of stress that a material can withstand before failure. In other words, it is the amount of force (compression, tension, shear, bending and torsion) necessary to break the part.

What are living hinges used for?

There are four different plastic hinge types used based on their design and strength. They are ideal for opening and closing without cracking or permanent failure in product parts. Notice that the hinge and radial lengths and thicknesses have increased. This results in a stiffer motion due to the increased hinge thickness. Figures 7 and 8 show the resulting 3D print of the design in nylon. Figure 5 shows the typical design of a flat hinge for injection molding.

Most cycle test usually give up around the million cycle mark so it is conceivable that they can last many more cycles. This visual guide highlights different types of hinges and their design and purpose. The success of your business is built in part on the speed and responsiveness with which you serve your customers – and so is ours. That’s why we meet (and often exceed) lead times from other manufacturers and ship products same-day, so that our hardware is in your hands as soon as possible. The thickness of the hinge greatly influences its operational feel, determining whether it feels stiff or loose. You may need to experiment with various thicknesses to find the optimal fit for your specific design.

Living hinge typically features a slender, elongated shape, often measuring anywhere from a few millimeters to a few centimeters in width. Their length can vary considerably, depending on the specific application, ranging from a few centimeters to several inches. The thickness of a living hinge is usually a fraction of a millimeter, designed to maintain flexibility while still providing structural integrity. A simple way to demonstrate how living hinges work or fail is with a thin piece of paper. Fold a sheet of paper loosely in half, but don't press down to crease it where it is bent.

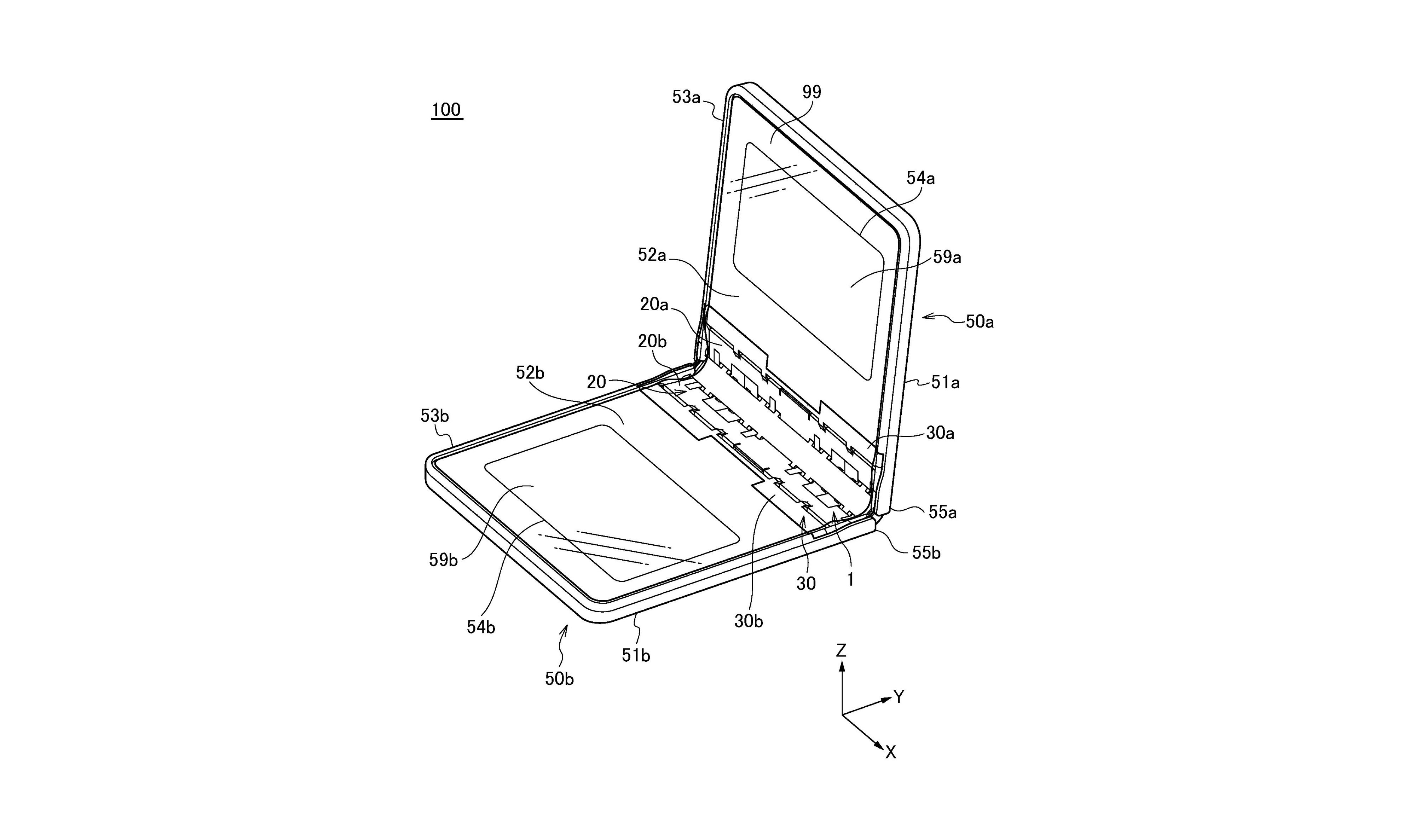

Patently untrue: Xiaomi and Huawei dispute over foldable design - Dao Insights

Patently untrue: Xiaomi and Huawei dispute over foldable design.

Posted: Fri, 15 Dec 2023 08:00:00 GMT [source]

There are two types of adjustments you might want to make to soft-close hinges - the speed of closure and the placement of the hinge itself. Although each hinge is different, most of them have three screws on the outside that can be used to adjust their alignment. Each UPVC door will have a slightly unique design, so it’s important to refer to your instruction manual before you start making any adjustments. Most UPVC hinges will have an adjustment slot behind a protective cap that can be unscrewed and lifted.

It is fast, cheap, and allows for mass production of living hinges once you decide on the prototype or the final hinge design. Each of these hinges needs to be fitted slightly differently so it can bear the load of the two elements, give the desired aesthetic and operate effectively. Brittle resins like polycarbonate simply aren't suitable for hinges.

Most conventional hinges require some type of pin like a screw or metal rod be inserted for the hinge to turn. Since a living hinge is a uni-body design you can eliminate those parts off the bill of material. Not only do you eliminate the hardware but you get rid of the hassle and cost of assembling the hinge. Furthermore, the radius of curvature along the hinge’s length is another critical dimension to consider. This radius can vary widely, depending on the material, the intended flexibility, and the overall design requirements.

By running these checks and making one adjustment at a time, you can help to fix any problems with your cupboard door’s alignment and ensure they open and close freely. Make sure your hinges fit perfectly with this guide on how to fit and adjust them. In most situations, you’ll be buying a custom concealed hinge, so get specific when discussing your goals with the hinge manufacturer. There are a number of similar experiments documented on Instructables, with many providing sample patterns you can try out yourself.

The living hinge design is such that it allows the product to bend and straighten multiple times without losing strength. As a final note, be careful of the types of materials that you use in your mechanical hinge solution. If you are fabricating a critical part, stick with the materials that have proven to have the tensile strength and are able to withstand strain over the life of the part.

No comments:

Post a Comment